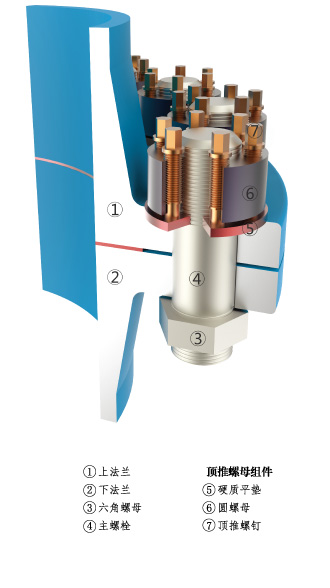

结构与原理

顶堆螺母组件由圆螺母及数个顶堆螺钉和一个硬质平垫组成,可用来直接替代传统的标准六角螺母。将其拧在螺栓、螺柱或带螺纹的杆、轴上,主螺纹将螺栓/螺柱上的圆螺母安置于硬质平垫上。圆螺母就位后,螺栓/螺柱的实际紧固通过手动工具拧紧主螺纹四周的顶堆螺钉即可,主螺纹承受纯拉力。

(1)顶堆螺钉摩擦直径小,使用较小的钮矩即可产生巨大的加紧力

By tightening the jackbolts,a strong thrust(axial)force is generated.This thrust force is directed against a hardened washer.Jackbolts against a hardened washer.Jackbolts have a small

friction diameter and can therefore create a high thrust force with relatively little torqut input.

(2)圆螺母可有效降低主螺纹应力而且可以直接替代标准螺母

The loads are transferred through the nut body which is postitioned on the main thread by hand.

(3)硬质平垫具有传递力及保护法兰面及本体的作用

A hardened washer is used to transfer the force while protecting the flange face.

(4)多个顶推螺钉的推力理与主螺栓帽的反作用力在法兰上产生巨大的夹紧力

The thrust(axial)force of many jackbolts and the opposite reaction force of the main bolt head create a strong clamping force on the flange.

(5)顶推螺钉的推力在主螺栓帽上产生同等的反作用力

The thrust(axial)force from the jackbolt creates an equally

strong reaction force in the main bolt